At Coeur de Xocolat, we’re not just chasing exquisite chocolate — we’re building systems that work at origin. That means systems that support smallholder cocoa farmers, adapt to local realities, and champion flavour development through smart, accessible fermentation practices.

At Coeur de Xocolat, we’re not just chasing exquisite chocolate — we’re building systems that work at origin. That means systems that support smallholder cocoa farmers, adapt to local realities, and champion flavour development through smart, accessible fermentation practices.

Because let’s face it — not every farmer has a fermentation shed, stacks of hardwood boxes, or a crew to move tonnes of beans between fermentation tiers.

So What’s the Alternative?

So What’s the Alternative?

Sometimes, it’s as simple as a bucket.

Or a shallow tray.

Or a well-managed cocoa pile — used wisely, with the right depth and regular turning.

The Hidden Hero of Cocoa Fermentation: Depth

Here’s the science you need to know:

Fermentation happens best at a depth of just 10 cm (about 4 inches).

Any deeper, and oxygen can’t circulate effectively. Microbial activity stalls, heat builds unevenly, and the beans may develop off-flavours or ferment inconsistently. And that’s a big problem when you’re trying to unlock the fine flavour potential of your cocoa.

This is why turning the beans — no matter the method — is essential. It reintroduces oxygen, regulates temperature, and ensures every bean has its moment in the microbial spotlight.

Tray fermentation, when done at that perfect 4-inch depth, gives you *unparalleled control* over the process.

Cocoa Fermentation Methods: What Works and Where

Here’s a breakdown of the most common fermentation methods used in cocoa production, from traditional to innovative, scalable to micro-lot:

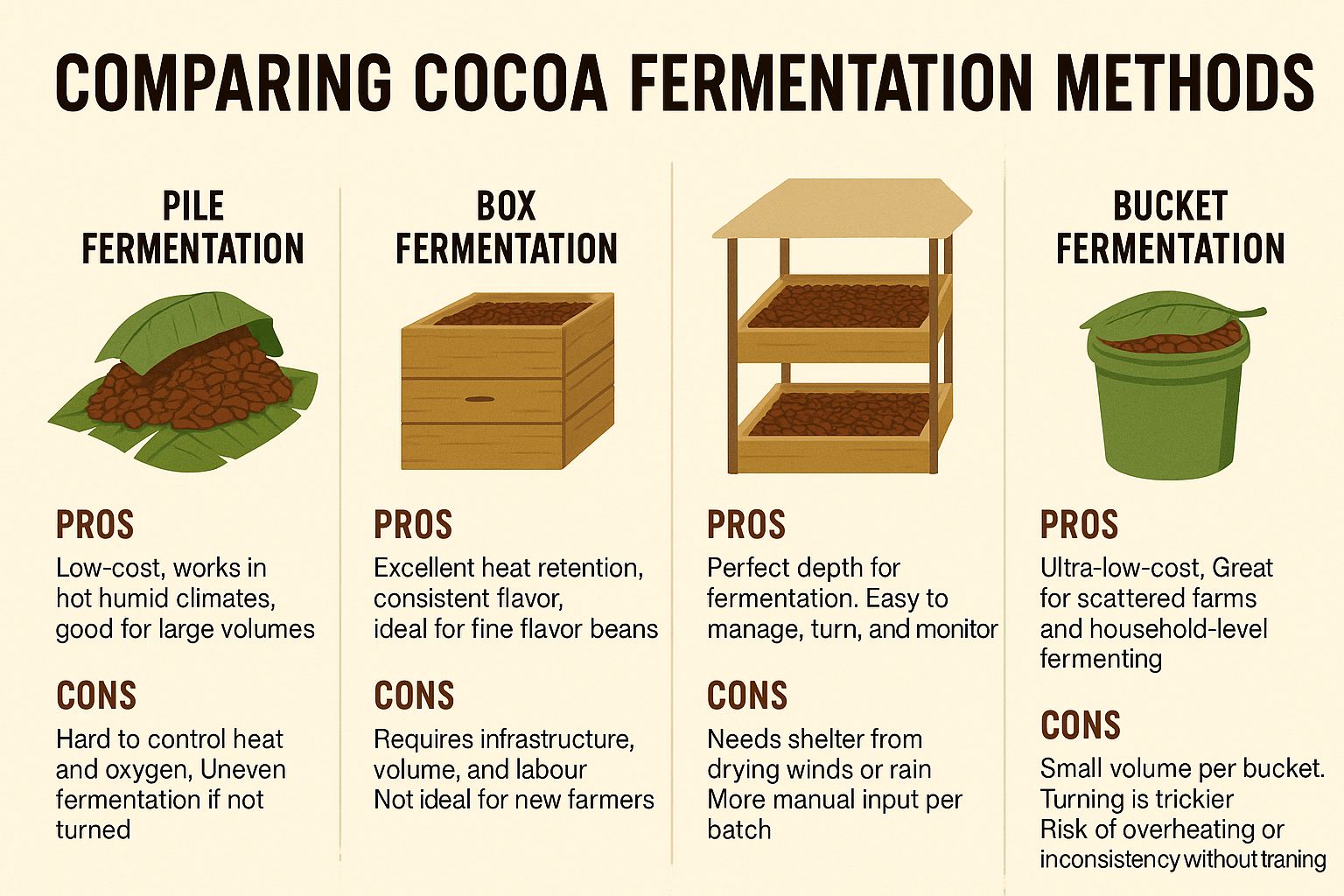

Pile Fermentation

Pile Fermentation

Simple, traditional, and scalable.

Beans are piled on banana leaves and covered with natural materials.

Pros:

Low-cost, minimal infrastructure

Works well in hot, humid climates

Suitable for large volumes

Cons

Challenging to control heat and air flow

Uneven fermentation without frequent turning

Box Fermentation

The gold standard for larger cocoa operations.

Beans are fermented in multi-tiered wooden boxes and turned periodically.

Pros:

Excellent heat retention and control

Consistent flavour development

Ideal for fine-flavour cocoa beans

Cons:

High infrastructure and labour requirements

Less accessible for new producers or remote regions

Precision fermentation for small batches and flavour experimentation.

Trays are stacked or laid under shelter, maintaining a uniform 4-inch depth.

Pros:

Superb microbial control and even fermentation

Great visibility for training and quality control

Allows easy drainage of excess mucilage

Cons:

Vulnerable to weather exposure

Labour-intensive for larger volumes

Bucket fermentation

The underdog method with serious potential.

Plastic buckets with drainage, covered with leaves or cloth.

Pros:

Ultra-low cost and easy to implement

Perfect for household-level or decentralised farmer networks

Promotes farmer skill-building and ownership

Great for emerging cocoa-growing areas

Cons:

Limited batch size

Must be manually stirred or transferred to turn

Requires training to avoid overheating or poor airflow

Spotlight: Why Bucket Fermentation Works in Malawi

In cocoa-producing countries like Malawi, where the crop is still developing, bucket fermentation isn’t a compromise — it’s a clever solution. With limited infrastructure, this method allows smallholder farmers to process cocoa at the household level in a decentralised, sustainable, and scalable way.

With the bucket version — including fermentation timing, depth control, and temperature management — we’re already seeing big improvements:

Better cocoa quality

Higher incomes for farmers

Renewed pride in the craft of cocoa production

“If you want even fermentation, think in centimetres, not kilograms.

Four inches? That’s microbial heaven.”

David Greenwood-Haigh

Do What Works — Not Just What’s Trendy

What works in Ecuador or Ghana might not work in East Africa or the Caribbean. And that’s okay. What matters is finding methods that fit the climate, the resources, and the *real-life rhythms* of cocoa farmers on the ground.

Whether it’s a bucket, box, Tray, orpile, the goal is the same:

Even fermentation. Beautiful flavour. And a system that builds value at origin.

Explore more about post-harvest processing, flavour education, and ethical cocoa sourcing in our blog series or join a Chocolate Safari® to see fermentation in action.*

#ChocolateWithPurpose #CocoaFermentation #PostHarvestMatters #CocoaEducation #EmpoweringFarmers #SmallholderSolutions #BeanToBarAtOrigin