Practical Guide for Farmers, Buyers, and Fine Chocolate Makers

The cocoa cut test is one of the most practical quality assessments available in cocoa production. It can be carried out quickly on the farm and provides immediate insight into how well cocoa beans have been processed from fermentation through to drying.

Used by farmers, producers, buyers, and inspectors, the cut test relies on direct sensory observation: sight, smell, touch, and structure. While more detailed flavour analysis is carried out later through roasting and tasting, the cut test remains a vital first checkpoint in evaluating cocoa quality and bean health

We often hear the term cut test but what is it well its the one analyses that can be done quickly by the farmer on the farm, producers and buyers can also check the quality of the processing, from the fermentation box/pile to the completion of the drying, using sensory methods smell, sight, sound and touch. (After drying, cocoa samples are roasted and a more indepth taste profile test carried out.) Cut tests can also be used to check cocoa bean health.

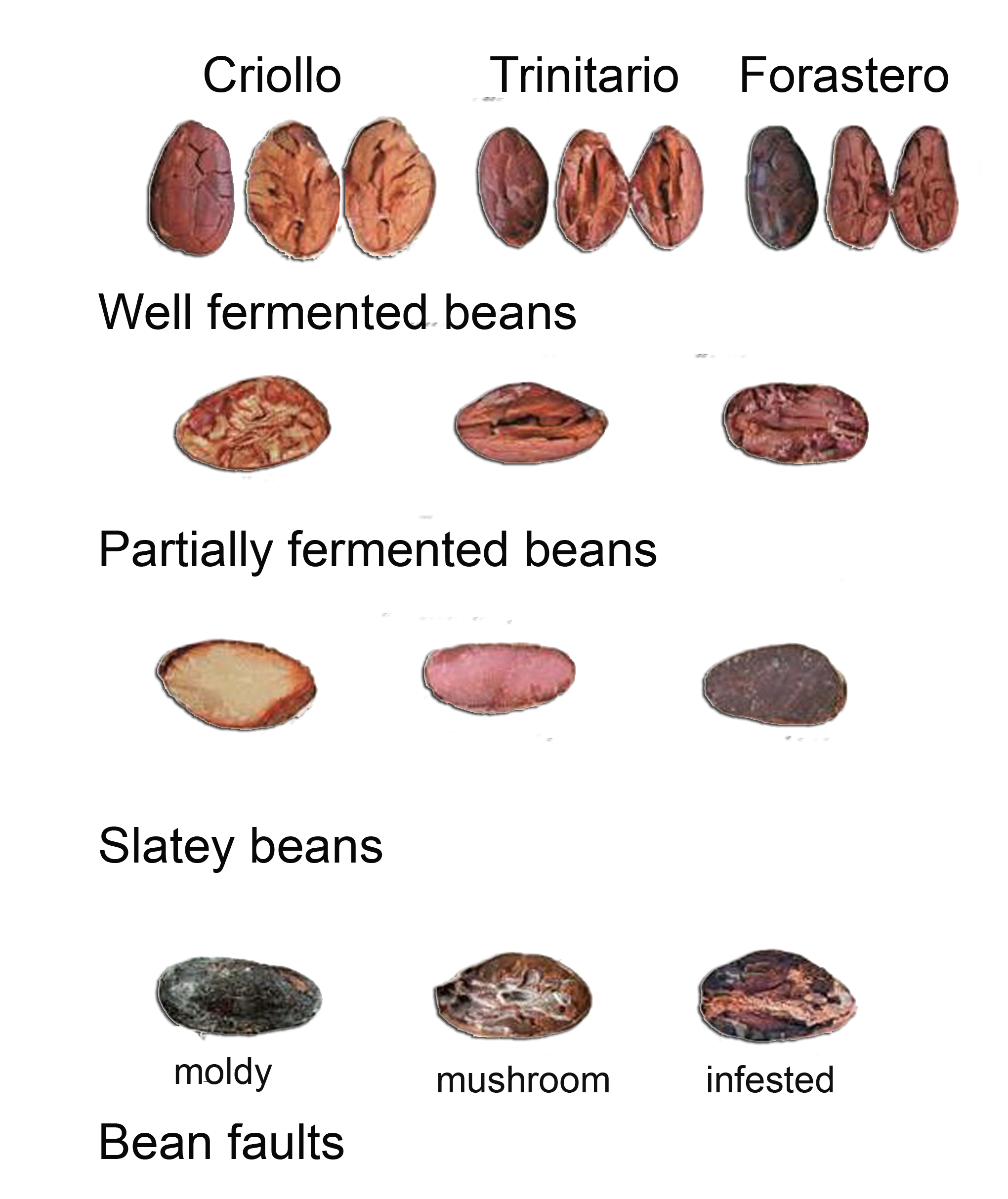

It’s basically opening up a cocoa bean by cutting it in two length ways to analyse the fermentation levels, its a quick way to identify any problems, like infestation or pest damage.

Farmers can also check that the bean's germ and cotyledon (the white web in raw cacao beans) have died, and check for any signs of mold.

If the beans have germinated or have mold, they shouldn’t be used for making chocolate.

How to do a cut test

Simply cut the fermented cacao beans in half to inspect their centres, this is normally done on a sample of at least ten beans from each batch.

At least 70% (7 in 10)of the beans should be fermented to the agreed level.

Cut tests should be done throughout the fermentation process.

Farmers can test and record a small amount of beans each day of the fermentation journey, to monitor progress and to check for any issues.

Once the beans have been put out on the drying tables, farmers might do some more cut tests. (with a guillotine) that holds about 50 beans at the end of processing, checking the overall fermentation level of each batch.

If a large number of samples in a batch have mold, are slaty (not grooved, but slick and greyish), or have germinated beans (the germ and/or cotyledon are still present), the batch is useless and should be destroyed. Farms that have more than one varieties of cacao can find it difficult reaching consistency in cut tests, each variety can respond to fermentation differently, so a batch with mixed varieties is unlikely to give consistent cut tests results.

Most guidelines have a standardised processing procedure.

At the buyer level, cut test requirements have precluded the exploration of cacao flavour profiles. Compare this to the world of coffee, where dark roast was once the standard. Now, people enjoy a range of roast profiles, which are connected to variety and processing choices.

Tools for performing the cocoa cut test

Tools for performing the cocoa cut test

If you can’t afford a guillotine, at around £1000-1200 for a Magra (a very nice tool from reports) then this is the most convenient tool, I’m a chef, so I know firsthand that knives just don’t cut it, it's hard to hold the beans still and make the cut without risking your digits.

but I remembered seeing a tool that my pimber used to cut a plastic pipe and thought I'd give it a try and it works just fine.

A trip to the DIY store and £5 later, I am now the proud owner of what appears to be a pretty serviceable one-bean-at-a-time solution.

I cleanly cut 10 beans in a couple of minutes, I would always say a guillotine will always be quicker and better but needs must and a pipe cutter will work.

Cut Tests and fine chocolate

The International Cocoa Organization (ICCO) and the world cocoa foundation have made it a requirement for large companies to use standardised cacao.

That’s, cacao that is fermented to the same point, so all tastes approximately the same. Buyers can easily measure that standard by checking the colour of the beans.

Beans that are at the correct level of fermentation will no longer be their natural purple or reddish colour, but a shade of brown. Inspectors use established guides to check the colour and aim for one uniform shade in the batch.

The standard states that cocoa beans should be:

- Free from any evidence of adulteration.

- Virtually free from living insects and other infestation.

- Virtually free from any foreign matter.

- Reasonably free from broken beans, fragments and pieces of shell.

- Fermented, then dried until their moisture content no longer exceeds 7.5% mass.

- Free from odour contamination.

- Within the standard for violet or purple beans, typical of the specified grade or origin.

- Reasonably uniform in size, fit for production of a foodstuff.

- Reasonably free from bean clusters, flat beans, germinated beans, residue and sieving’s.

The Grade Standards lay down the following maximum limits for producing country internal classification for fermented beans: - ISO 2451 now also specifies bean size standards, defined by the bean count and usually expressed by the number of beans per 100g The current specifications are:

| Large beans: | Bean count of less or equal to 100 |

| Medium beans: | Bean count of 101 to 120 |

| Small beans: | Bean count greater than 120 |

|

Grade |

Mouldy |

Slaty |

Damaged, Flat, doubles, germinated |

| One | 3% | 3% | 3% |

| Two | 4% | 8% | 6% |

cocoa grading is becomming more sophisticated with a much more holistic approach, where cut tests are just one consideration, rather than the whole analysis. Slowly, the industry is adopting more nuanced methods to evaluate quality and allow room for individual features and preferences.

cocoa grading is becomming more sophisticated with a much more holistic approach, where cut tests are just one consideration, rather than the whole analysis. Slowly, the industry is adopting more nuanced methods to evaluate quality and allow room for individual features and preferences.

Collaboration between fine chocolate-makers and producers could lead us to a point where buyers could order beans fermented to their preference, just as a customer in a restaurant can order their steak rare, medium, or well-done.